Pharma & Healthcare

Versatility, robust performance, and above all, security are essential to industrial data communications in pharamceutical manufacturing and the healthcare industries. Plant managers, automation engineers, and health services professionals around the world choose DataHub® software for its proven track record in providing flexible and secure system integration solutions.

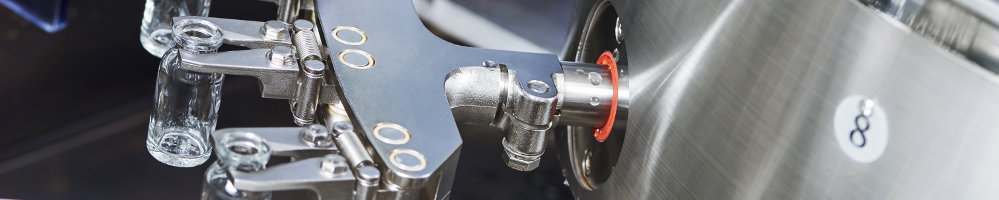

API and Device Manufacturing

The DataHub program can be found in mission-critical manufacturing plants for both active pharmaceutical ingredients and medical devices. Its ability to integrate OPC DA and UA, support secure networking, and provide hot-standby redundancy allow plant engineers to optimize the use of their installed equipment base while ensuring the highest possible quality of finished product.

Healthcare and Services

Acting as a middleware agent, DataHub software maintains a vital link between a wide variety of patient monitoring equipment on the one hand, and a range of complex support programs on the other. Whether their devices connect using standard data protocols like OPC or Modbus, or need to interface via custom programs, healthcare system designers can quickly and easily bring solutions to market, knowing that data communication is a solved problem.

Use Cases

Drug Synthesis Process Management: Process engineers at a facility in the Middle East used the DataHub program to connect drug synthesis production data to the company MES system in real time.

Patient Monitoring System: OPC-enabled patient monitoring equipment connected to DataHub software feeds critical statistics in real time to wall-mounted displays for nurses, doctors, and hospital staff.

Filling and Packaging Line OEE: Connecting a DataHub instance to filling and packaging production lines, plant engineers can collect data in real time to improve OEE for the plant.

Integrating Monitor Status Data: A device manufacturer is using DataHub software to integrate the status data from different monitoring machines and providing combined HMI displays.

Medical Device Manufacturing: The DataHub program was used to establish dual-channel redundant communication between the MES and SCADA applications of a medical device manufacturer.

API Production: The data from two production systems was combined and displayed in two SCADA systems at an API production plant in Europe, using DataHub software.